Artificial Intelligence algorithms in e-commerce warehouse of LPP

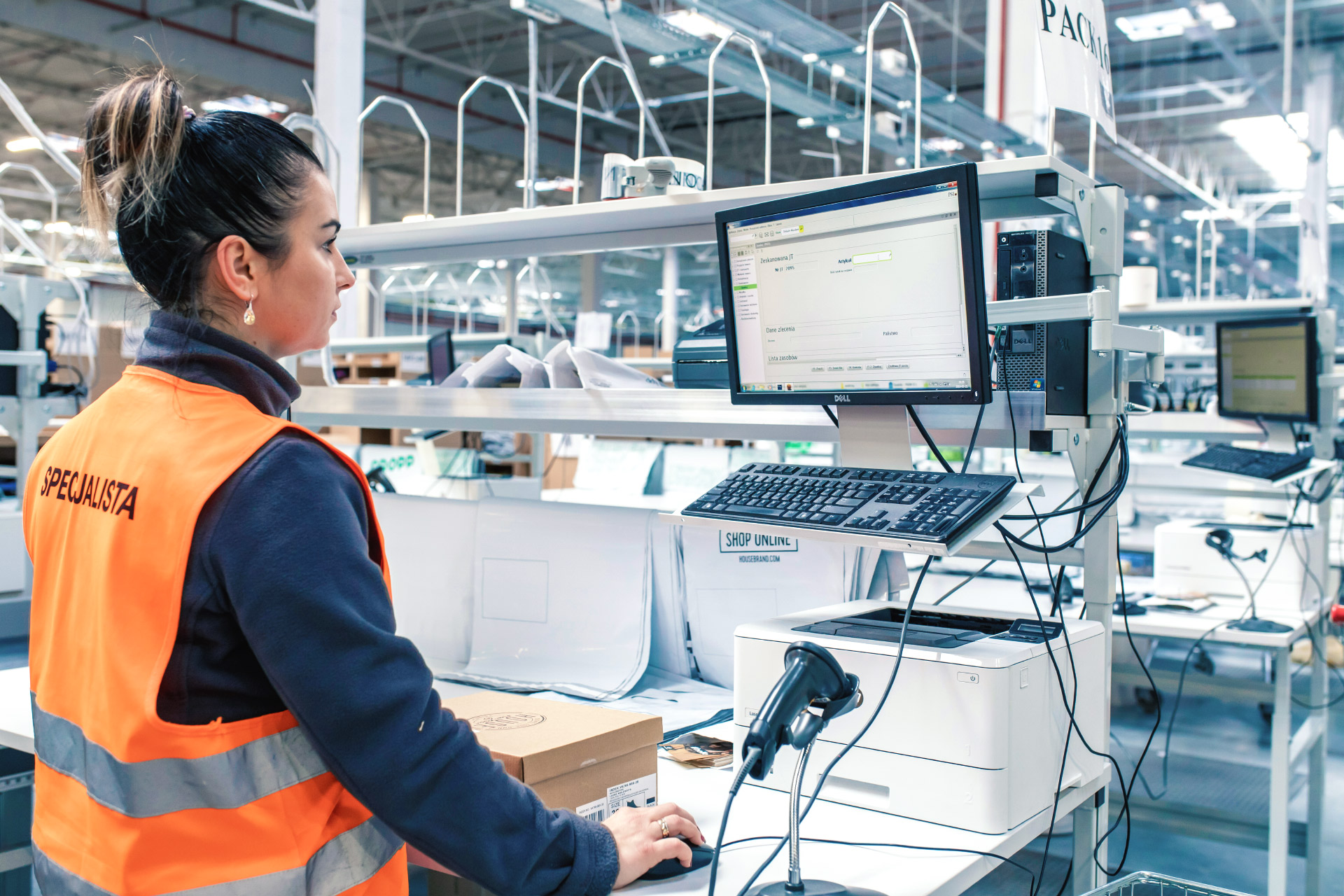

In the LPP warehouse handling online sales orders (Fulfilment Centre), a solution optimising order picking path using Artificial Intelligence algorithms has been implemented. This innovative system, which is an element of the Warehouse Intelligence project, is the result of cooperation between LPP and PSI Polska –an industrial software producer. The use of the machine learning mechanism in the warehouse of the Polish clothing company allows to shorten the path needed for order picking, increase the efficiency of the facility, optimise the use of warehouse resources and significantly speed up the handling of e-commerce shipments.

LPP, together with PSI Polska, a producer of software for industry, implemented an innovative solution to optimise the order picking path using Artificial Intelligence in the Fulfilment Centre-type warehouse belonging to the Polish clothing company. This is a response to the growing volume of online orders and a clear change in the market share of this sales channel.

LPP, the owner of Reserved, Cropp, House, Mohito and Sinsay brands, handling about 11 million orders a year, is one of the leaders of the e-commerce market in Poland and Europe. The dynamic growth of online sales, also in connection with the Covid-19 epidemic, poses an increasing challenge to meet the growing demand of customers for online shopping. Last year, the share of online sales in LPP operations was 12%. However, the pandemic has significantly changed the balance of power between the traditional and online channels. – At the moment, we are observing as much as a 4-fold increase in customer interest in online shopping. This determines the need to optimise logistics and IT solutions aimed at meeting new customer expectations without compromising the quality and, above all, the speed of handling online orders – says Jacek Kujawa, Vice-President of the Management Board of LPP. Therefore, together with our long-standing business partner, PSI Polska, we decided to implement a solution based on Artificial Intelligence algorithms, which will allow us to significantly increase the efficiency of online order processing, he adds.

Thanks to the warehouse management system (WMS), LPP guarantees its customers that the ordered products will reach them quickly and without any problems. – The main task of the implemented algorithm is to effectively solve the so called “travelling salesman problem”, TSP – comments Jerzy Danisz, PSIwms System Standard Development Manager in PSI. It consists in determining the shortest route connecting several points on the map. In the case of a warehouse, the system must determine the optimum route for several dozen picking locations. What seems simple at first glance in fact has been posing a significant problem for mathematicians for years – concludes Jerzy Danisz.

Therefore, LPP and PSI Polska have decided to prepare a solution based on Artificial Intelligence algorithms. The use of a machine learning mechanism, namely a neural network based on CNN units (Convolutional Neural Network) , allows to generate lists of products needed to complete an order in real time, determine the shortest path and propose optimum use of resources, including equipment, trolleys and time of warehouse employees. This is done, among other things, through the use of the so-called genetic algorithm, which, through the application of evolutionary operators (such as crossing and mutations), allows to create an optimum picking list.

– Thanks to the implemented solution, as the first tests demonstrate, the length of picking paths was reduced by 30%. This also translates into a significant increase in the efficiency of the warehouse picking process itself by as much as 12.3%, explains Sylwester Dmytriwski, E-commerce Fulfilment General Manager in LPP. The algorithm not only allows for a reduction in the distance required for order picking. Thanks to the Artificial Intelligence module, the mechanism “learns” on the basis of the information it has. It absorbs data concerning the warehouse, orders and available personnel. On this basis, it groups products, facilitating the whole process, adds Sylwester Dmytriwski. Thanks to continuous cooperation with other modules of the resource management system, the implemented solution is able to update the information it has in real time and adjust the generated lists.

The picking path optimiser is an element of the Warehouse Intelligence project, whose concept, based on the use of Artificial Intelligence, has been appreciated by a team of experts from the National Centre for Research and Development in Warsaw and recommended for funding of the project. Good cooperation and the use of agile implementation methodologies allowed PSI and LPP to smoothly introduce an innovative solution that brings satisfactory results already in the first phase of the project. We have been cooperating with LPP for years. During this time, the PSIwms system allowed for handling more than 10-fold increase in volume in distribution centre of LPP in Pruszcz Gdański. We are glad that LPP has also chosen us to handle its e-commerce processes. The ability of LPP team to quickly implement innovations and react to changes is appreciated and inspiring for us, concludes Arkadiusz Niemira, CEO of PSI Polska.

___________________________________________________________________________

PSI Polska Sp. z o.o. located in Poznań is a part of an international corporation – PSI Software AG – which, based on its own software, provides comprehensive solutions for effective management of the energy and goods supply chain. PSI was founded in 1969 and has a headcount of 2000 employees worldwide. The 300-strong team of PSI Polska develops software for the needs of the whole corporation and carries out system implementations in Poland and abroad. In Poland, PSI software solutions have been used by, among others, ABM Greiffenberger, ArcelorMittal, CCC, DMG Mori, Empik, Inter Europol, LPP, MPK Poznań, Nałęczów Zdrój / Cisowianka, Piątnica, Stelweld, Volkswagen.

LPP SA is a Polish family business and one of the fastest growing clothing companies in the region of Central and Eastern Europe. For over 25 years it has been successfully operating in Poland and abroad, offering its collection already on 25 markets, including in such prestigious capitals as London, Berlin, Tel Aviv or Moscow. LPP SA manages five fashion brands: Reserved, Cropp, House, Mohito, and Sinsay. The company has a chain of over 1700 stores with the total area of over 1 million sq.m. The online offer of the brands collections is available on 31 markets. On the basis of a global supply chain, the Polish clothing producer distributes over 265 million pieces of clothing to three continents. LPP plays another important role as it employs over 24 thousand people in its offices and sales structures in Poland, Europe, Asia, and Africa. The company is listed on the Warsaw Stock Exchange in the WIG20 index and belongs to the prestigious MSCI Poland index.